Designing a Wrist Strap for Cameras

1. Why

I’ve love taking photots and I have collected a bunch of old and new cameras over the years, so naturally I was looking for a wrist strap to not drop any of them. I didn’t like what I found online though, because I felt nobody sells a camera strap that is both functional and stylish but doesn’t brake the bank. The requirements were, that it had to look high quality and be easy to manufacture.

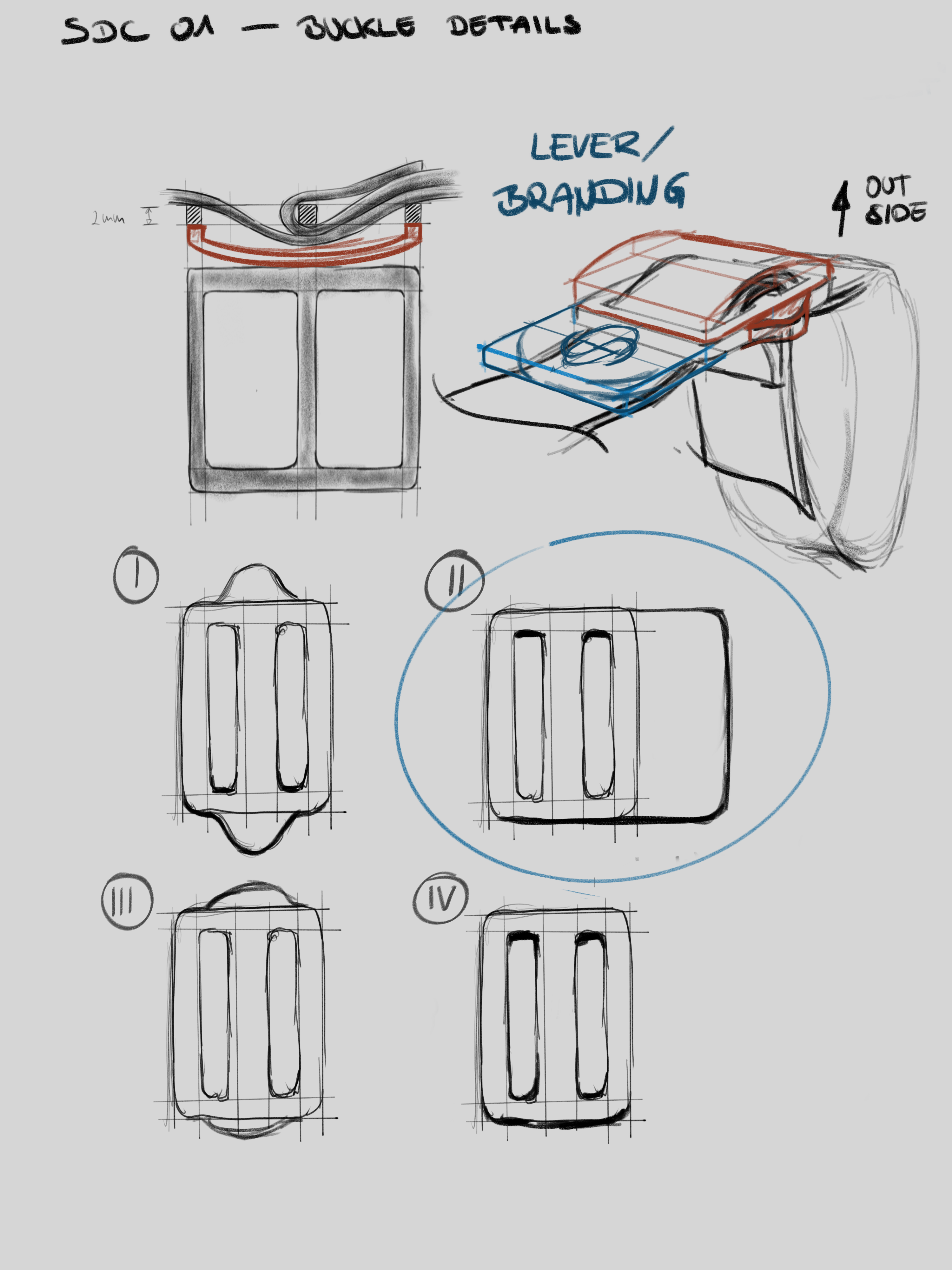

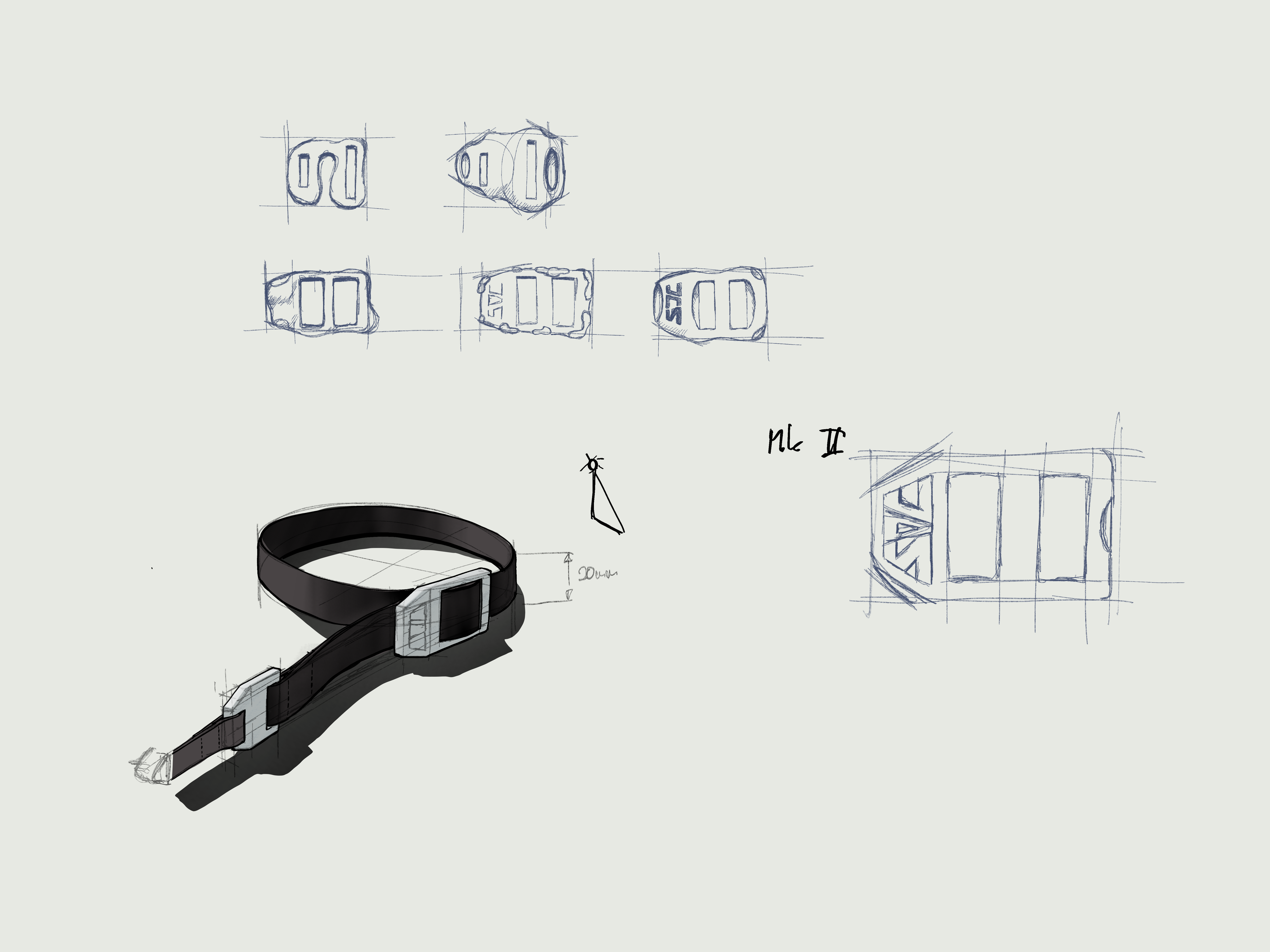

While being very simple, the details in the design are intruiging to me. How does the slide buckle have to be dimensioned to work just right? How easy should it be to move and does the force needed to move the buckle decrease over time? And finally how do you make this very simple thing cheap but not boring?

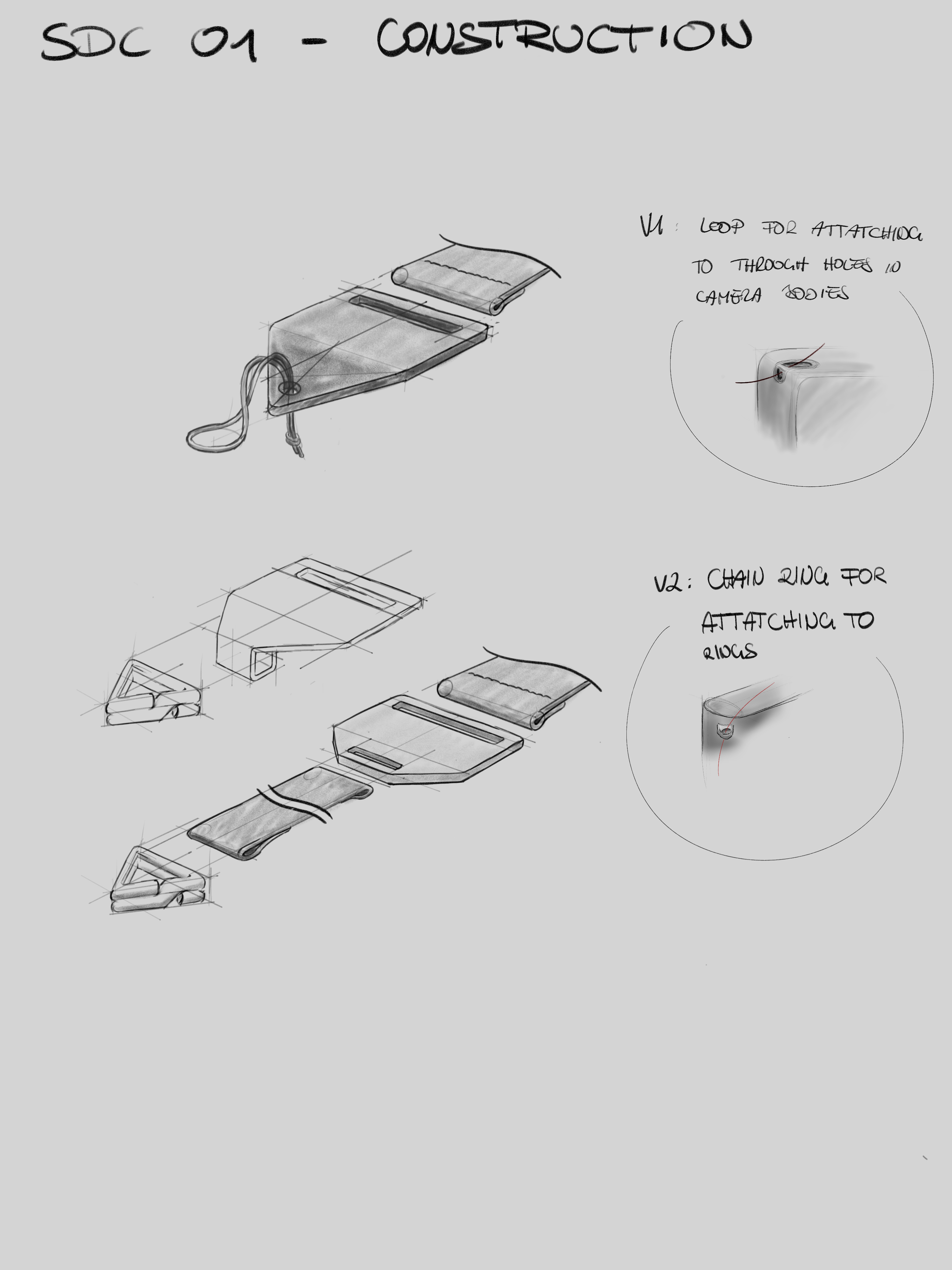

2. First Sketches

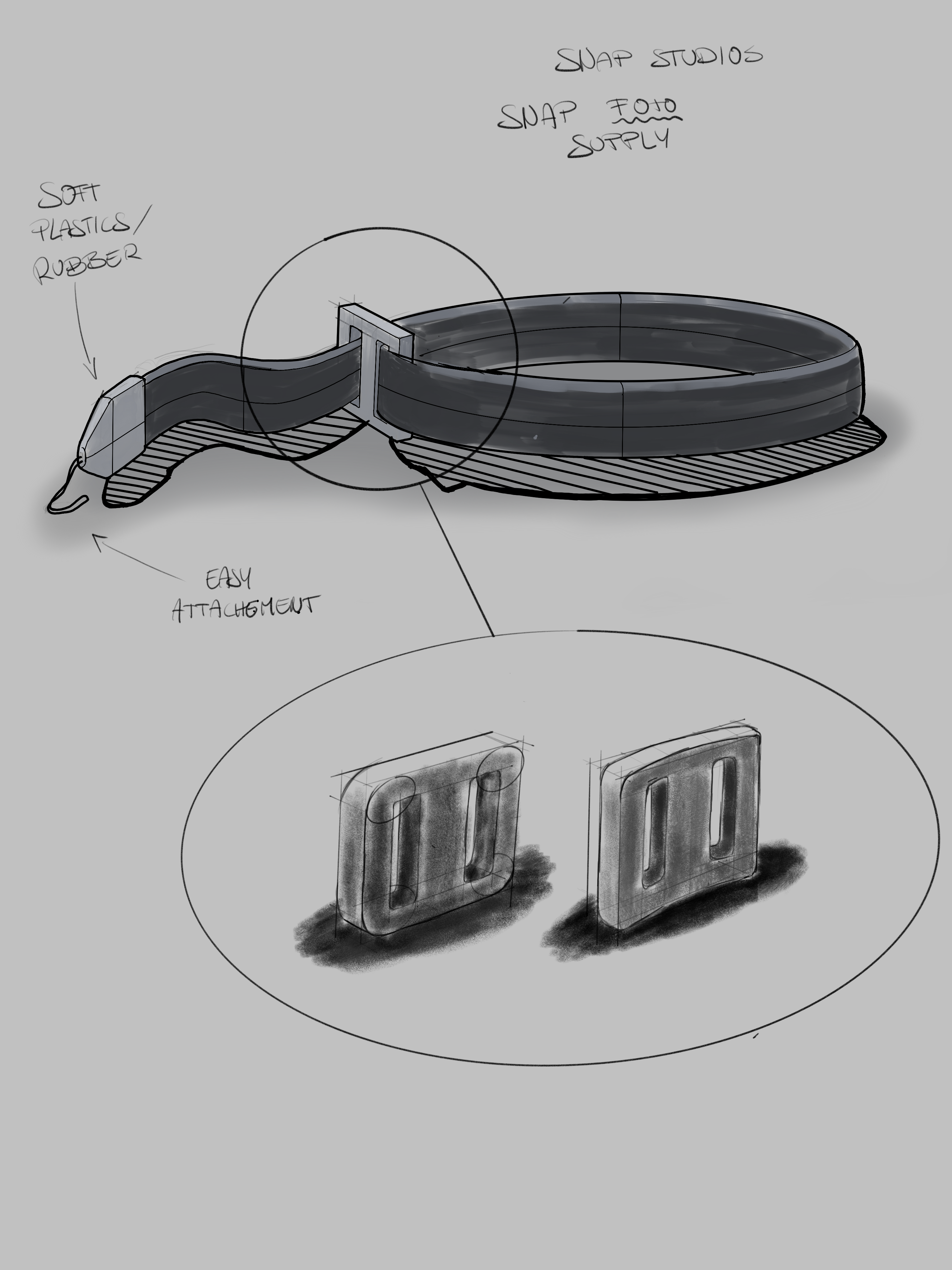

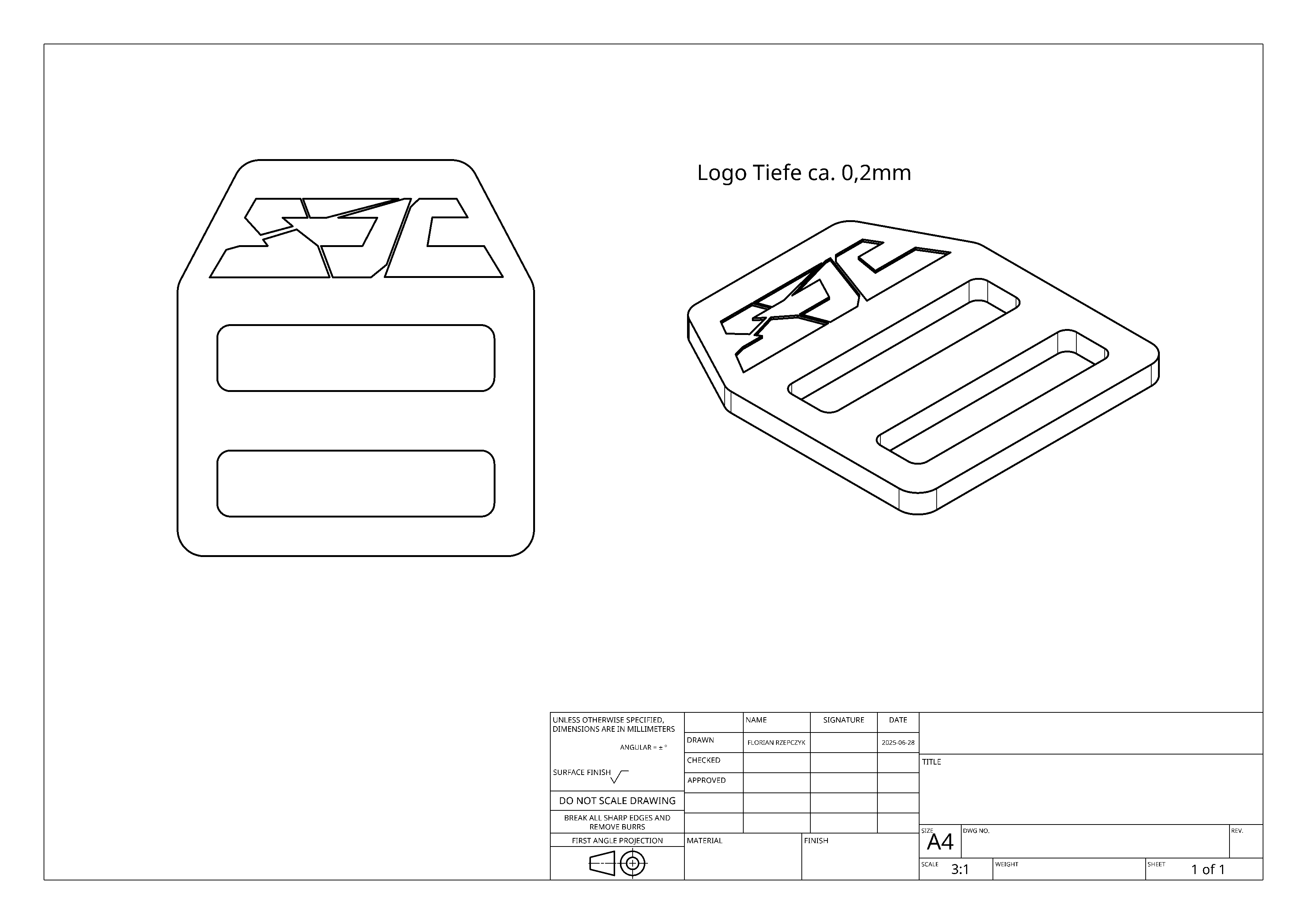

Early one I decided I wanted to with laser cutting as the manufacturing method for all the hardware. That drops the manufactring cost and is easily scalable. But it meant, that I had to design everything without details in the vertical axis.

On the oher hand it allows us to use metal parts to improve the feel and quality of the product at a low cost.

3. Details

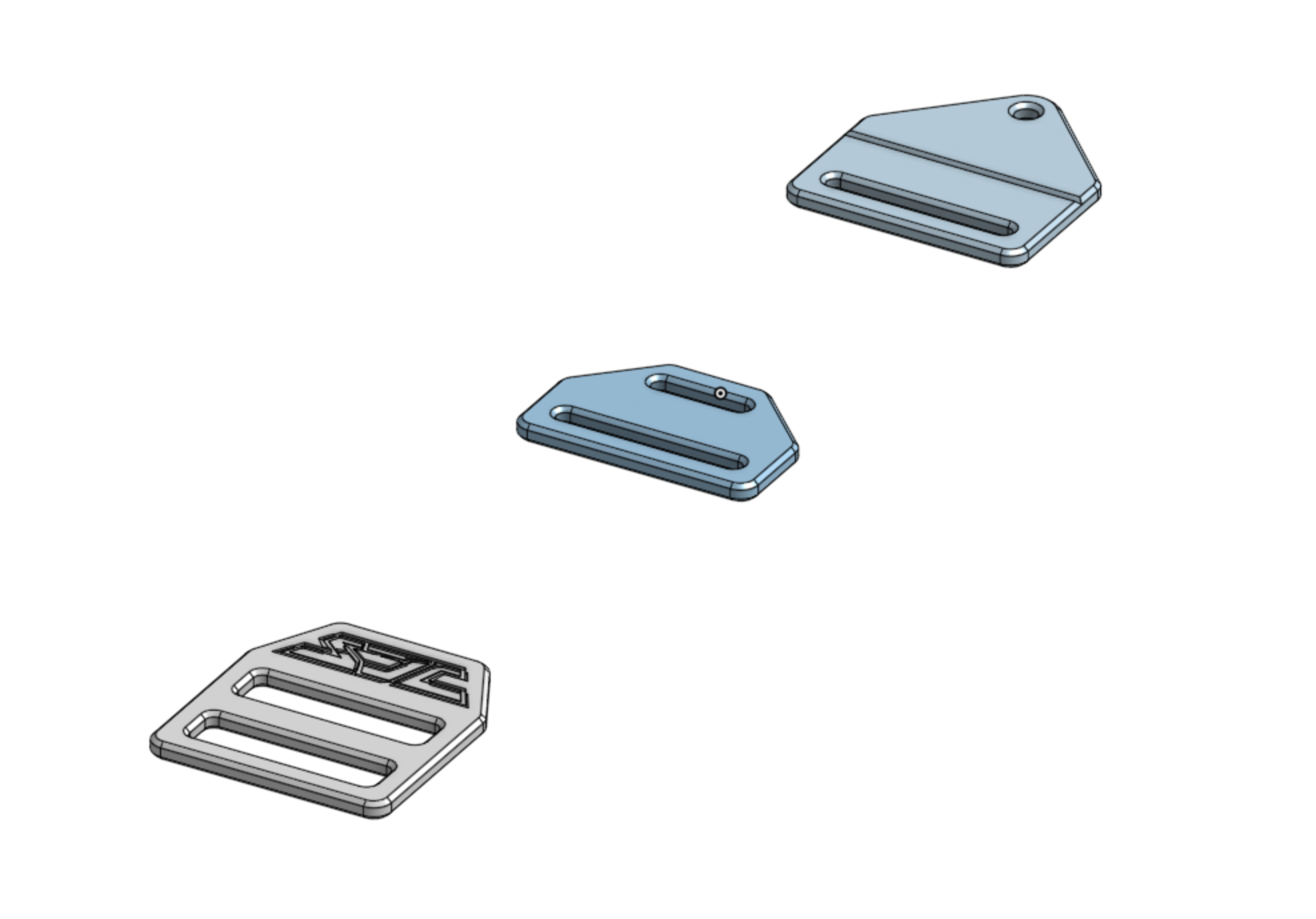

4. CAD

5. First Prototype

To decide on the final dimensions I printed the critical middle part in multiple versions and setup a testing matrix to find the ideal one for each of the strap materials I tested. Resulting in a Matrix to evaluate materials and denote the corresponding ideal width of slot in the slide buckle.

I landed on a premium cotton weave, 24mm in width. The feel and cost were superior to the other 6 options that were tested. That decision left me with the slot width of 4mm working best. Giving a solid and secure feel, but the buckle is still easily adjustable.